mechanical design

With the end goal of seamless electromechanical integration, I designed the racer & controller with the following criteria:

“Massive”

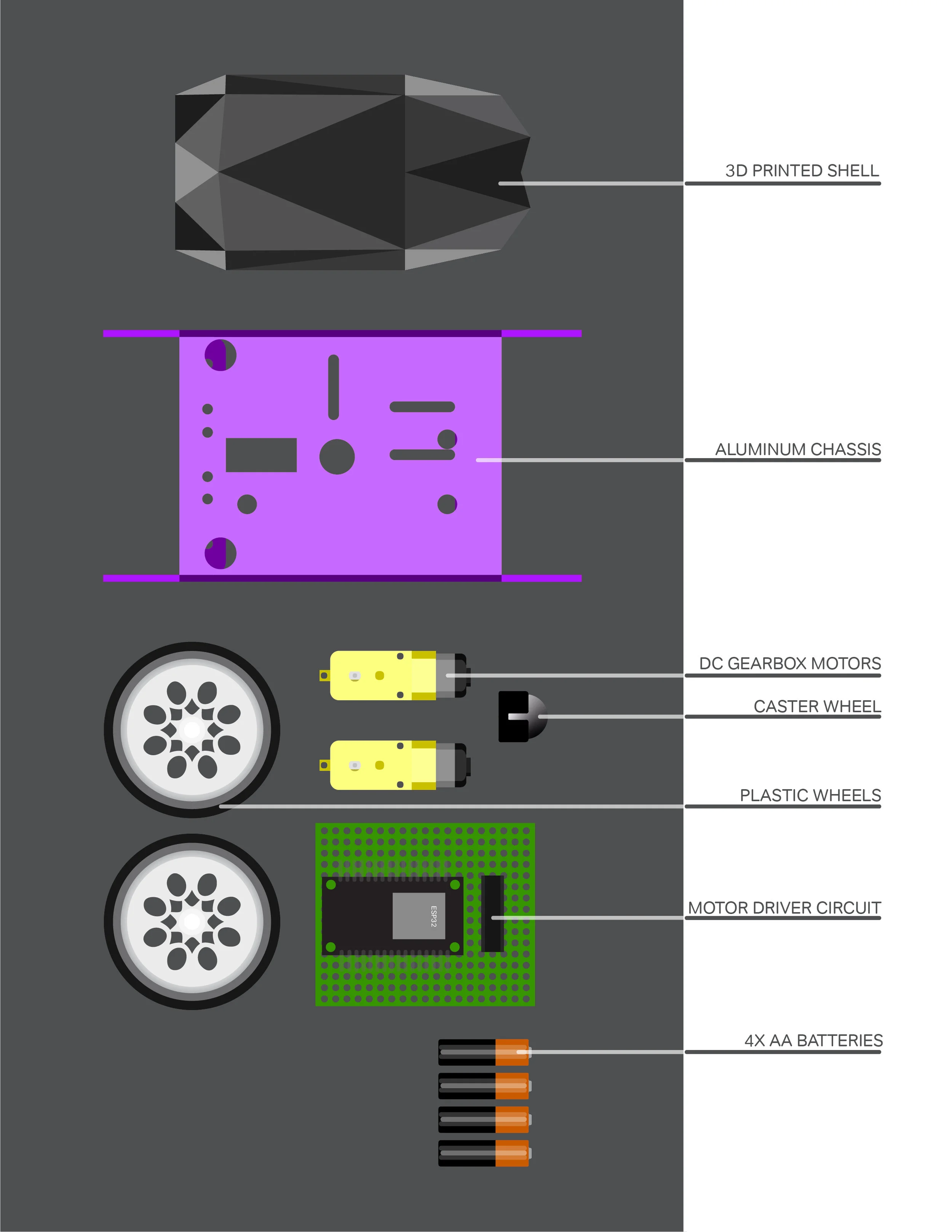

The constraints of the assignment favored heavier cars, and thus we incorporated an anodized aluminum chassis that provided structure as well as a low center of mass, housing the components low to the track. This allowed the racer to easily traverse the course and mitigate tipping up the ramp.

Agile

A challenge in the mechanical design was fitting the components into a compact, aerodynamic form while being able to drive well during the races. The minimum clearance of the track was 5” and thus the racer was dimensioned accordingly, measuring in at 5 x 7.” To achieve responsive yet simple dynamics, I incorporated a differential drive system with the addition of a low friction caster wheel for turning support and stability. Plastic gearbox motors provided enough torque to drive the wheels directly and interfaced well with existing high traction tires.

Durable

The race involved 3 cars simultaneously attempting to navigate a tight track. I designed a 3D printed shell to protect the perf boards with the additional goal of giving the vehicle a high visual status. The chassis provided additional bumper protection against other racers or the track barrier itself.

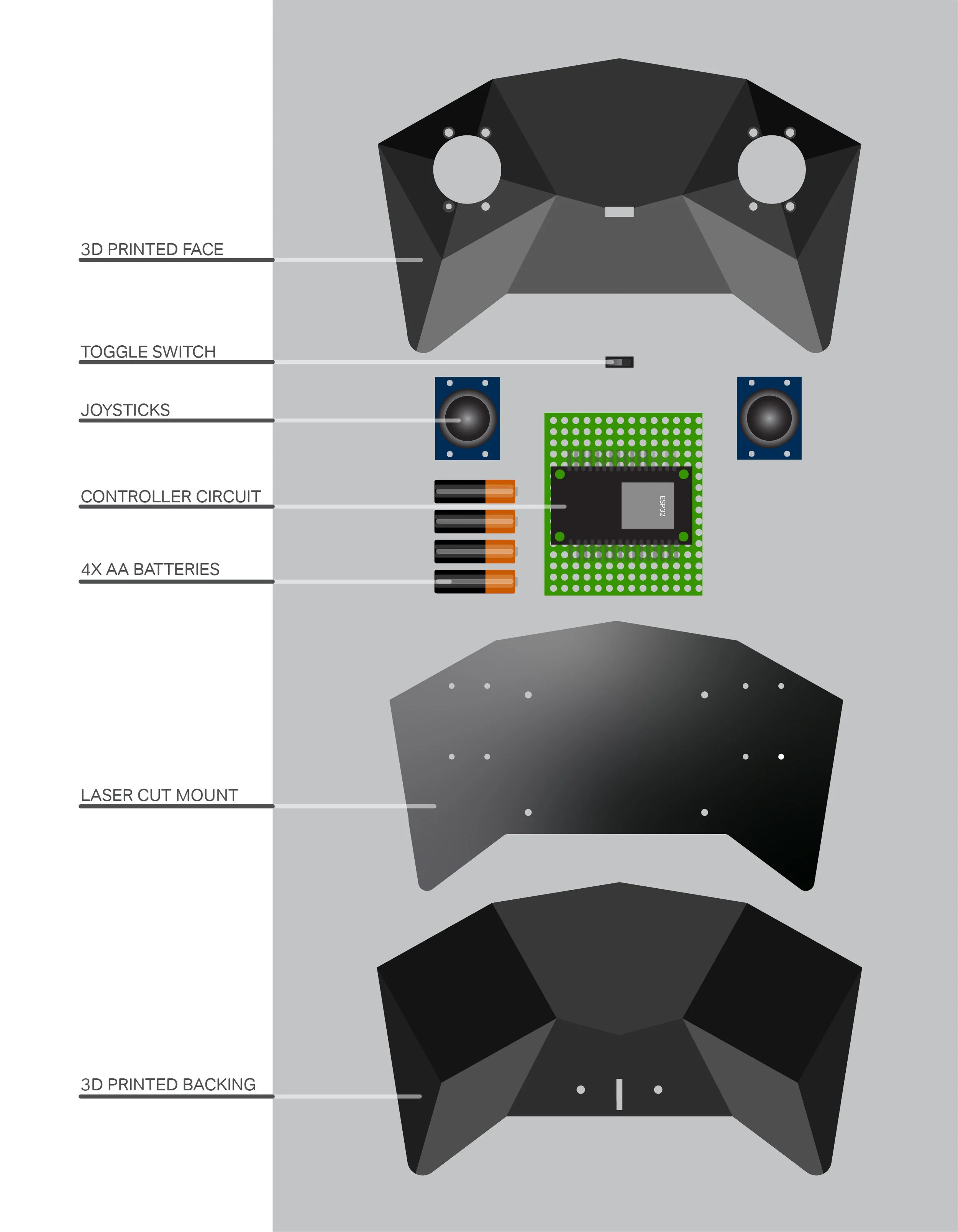

The controller was designed mainly to house the joysticks and circuitry, but in an ergonomic form that alluded to the racer’s visual language. An unobtrusive toggle switch was added to increase usability and preserve battery.